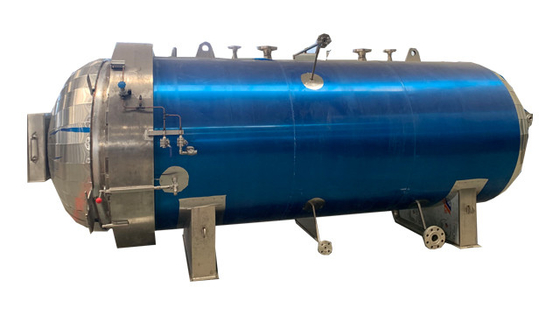

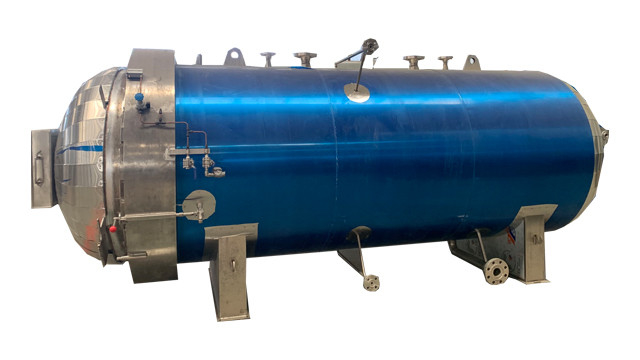

10mm 12mm 14mm Custom Rubber Vulcanization Autoclave Air Cooled Pressure Autoclave PLC Control

Product Description:

The Rubber Curing Autoclave is an automatic autoclave, meaning that it requires minimal operator input, making it easy to use and maintain. This autoclave is ideal for rubber manufacturers who require an efficient and reliable curing chamber for their rubber products. It is designed to provide consistent and uniform curing for all types of rubber products, ensuring that each product is of the highest quality.

The Rubber Curing Autoclave is also known as a Vulcanization Autoclave, which is used in the process of vulcanization. Vulcanization is a process that involves curing rubber products by exposing them to heat and pressure inside an autoclave. This process is essential for producing high-quality, durable rubber products that are resistant to wear and tear.

The Rubber Curing Autoclave is designed to provide a safe and reliable curing environment for rubber products. It is equipped with a number of safety features to ensure that the curing process is safe and efficient. The autoclave is also designed to be energy-efficient, reducing energy costs and minimizing the impact on the environment.

The Rubber Curing Autoclave requires a power supply of 380V/50Hz to operate. This makes it compatible with most standard electrical systems. It is also easy to install and requires minimal maintenance, making it a cost-effective solution for rubber manufacturers.

In summary, the Rubber Curing Autoclave is a high-quality, reliable, and efficient vulcanization autoclave that is designed to provide consistent and uniform curing for rubber products. It is an ideal choice for rubber manufacturers who require a safe, reliable, and cost-effective curing chamber for their rubber products. Whether you are producing rubber hoses, seals, gaskets, or any other rubber products, the Rubber Curing Autoclave is the perfect solution for your needs.

Features:

- Product Name: Rubber Curing Autoclave

- Safety Device: Pressure Switch, Safety Valve

- Power Supply: 380V/50Hz

- Ventilation Mode: Forced Ventilation

- Heating Mode: Electric Heating

- Keywords: Vulcanization Autoclave, Rubber Curing Chamber

Technical Parameters:

| Safety Device |

Pressure Switch, Safety Valve |

| Power Supply |

380V/50Hz |

| Cooling Mode |

Air Cooling |

| Insulation Mode |

Foam Insulation |

| Weight |

Customized |

| Ventilation Mode |

Forced Ventilation |

| Control System |

Semi-automatic Or PLC Control |

| Operation Mode |

Automatic |

| Thickness |

10mm 12mm 14mm(can Be Customized) |

| Material |

Q345R Carbon Steel Or Stainless Steel |

Applications:

The Rubber Vulcanization Autoclave has a pressure of 0.85Mpa, which makes it ideal for use in the rubber industry. The autoclave is available in different insulation thicknesses of 10mm, 12mm, and 14mm, which can be customized to suit your specific requirements. The control system of the autoclave can either be semi-automatic or PLC, depending on your preferences and needs. The cooling mode of the autoclave is air-cooling, which makes it easy to use and maintain.

The Rubber Curing Chamber is certified with ISO and CU-TR, which is a testament to its quality and performance. The minimum order quantity for the Rubber Vulcanization Autoclave is 1 set, and the price is negotiable. The packaging of the autoclave is nude packing, and it can be shipped by containers or bulk cargo. The delivery time for the autoclave is 35 days after payment is received. The payment terms for the autoclave are T/T, L/C, D/A, D/P, Western Union, and MoneyGram. The Rubber Vulcanization Autoclave has a supply ability of 5000 sets per year, which ensures that you can always have access to this essential piece of equipment.

The Rubber Vulcanization Autoclave is essential for industries that manufacture rubber products. It guarantees the proper curing and vulcanization of your rubber products, which ensures that they are of high quality and meet industry standards. The Rubber Curing Chamber is suitable for various applications such as the production of rubber hoses, tires, and rubber sheets. It is a reliable and efficient tool that will provide you with excellent performance for years to come.

Customization:

Support and Services:

The Rubber Curing Autoclave product comes with technical support and services that include:

- Installation and commissioning

- Operator training

- Maintenance and repair services

- Remote diagnostic services

- On-site technical support

- Replacement parts and accessories

- Calibration and validation services

Our team of experienced technicians is dedicated to ensuring that your autoclave is working efficiently and effectively to meet your production needs.

Packing and Shipping:

Product Packaging:

The Rubber Curing Autoclave will be packaged securely with foam and bubble wrap to ensure safe transportation. The package will also include an instruction manual and all necessary components for installation and use.

Shipping:

The Rubber Curing Autoclave will be shipped via a reliable courier service to the designated address provided by the customer. The estimated shipping time will be provided upon order confirmation and may vary depending on the destination. Customers will be provided with a tracking number to monitor the delivery status of their order.

FAQ:

Q: What is the brand name of the product?

A: The brand name of the product is LUY.

Q: What is the model number of the product?

A: The model number of the product is DN 1500 3000.

Q: Where is this product made?

A: This product is made in China.

Q: Is this product certified?

A: Yes, this product is certified with ISO and CU-TR.

Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set.

Q: What is the price of this product?

A: The price of this product is negotiable.

Q: How is this product packaged?

A: This product is packaged in nude packing and can be shipped by containers or bulk cargo.

Q: What is the delivery time for this product?

A: This product can be shipped in 35 days after receiving payment.

Q: What are the payment terms for this product?

A: The payment terms for this product are T/T, L/C, D/A, D/P, Western Union, and MoneyGram.

Q: What is the supply ability of this product?

A: The supply ability of this product is 5000 sets per year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!