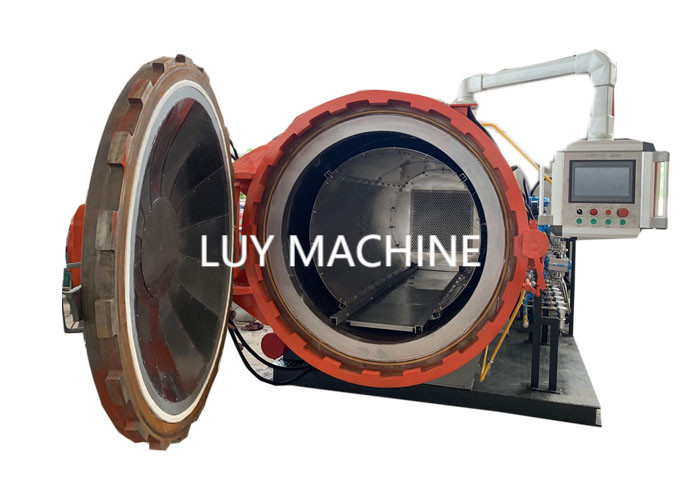

Carbon Fiber Composite Curing Autoclave 0.5 - 5Mpa 15m Effective Length

Product Description:

Composite Autoclave is an industrial autoclave machine with automated pressure autoclaves, specifically designed for the manufacturing process of carbon fiber autoclave. It comes with a test vacuum port, which is separated from the vacuum and test, and a pressure error of 0.01Mpa. The working pressure of this autoclave is between 0.5-5Mpa, and its tank material can be made of Q345R, SS304, 316 or ASME material. It also has a cooling rate of 0-7°C/min, making it an ideal choice for the production of carbon fiber.

Features:

- Product Name: Composite Autoclave

- Working pressure: 0.5-5Mpa

- Cooling ways: Wind cool or water cool

- Heating rate (empty load): 0-7°C/min

- Effective length: 1-15m

- Test vacuum port: 1-50 vacuum and test is separated

- High temperature carbon fiber autoclave for composite process

Applications:

Composite Autoclave: A Versatile Industrial Autoclave Machine for Composite Materials Processing

Composite Autoclave is a versatile Industrial Autoclave Machine for Composite Materials Processing. It is an ideal choice for carbon fiber autoclave applications and is capable of handling a wide range of materials, including composites, laminates, and other materials used in industrial processes. Its working pressure ranges from 0.5 to 5Mpa and is equipped with both electricity and wind-cool or water-cool heating and cooling ways. With an effective length of 1 to 15m and a pressure error of 0.01Mpa, the Composite Autoclave provides precise and reliable temperature control to ensure consistent and accurate results. This makes it an ideal choice for autoclave process composite applications, including composites processing, lamination, and other industrial processes.

The Composite Autoclave offers a wide range of features and benefits, including precise temperature control, reliable operation, and consistent results. Moreover, its quick setup time and ease of operation make it an ideal choice for industrial applications. With its robust construction and durable design, the Composite Autoclave is capable of withstanding high temperatures, pressures, and other harsh conditions. This makes it an ideal choice for a variety of industries, including aerospace, automotive, and construction.

The Composite Autoclave is an ideal choice for applications that require fast and efficient processing of composite materials. Its precise temperature control and reliable operation make it a reliable choice for industrial processes. Moreover, its durable construction and design ensure that it can withstand harsh conditions and provide reliable and consistent results. With its versatility and reliable operation, the Composite Autoclave is an ideal choice for industrial autoclave machine applications.

Technical Parameters:

| Parameter |

Value |

| Working temperature |

100-450 degree |

| Working pressure |

0.5-5Mpa |

| Cooling ways |

Wind cool or water cool |

| Tank material |

Q345R or SS304 316 OR ASME material |

| Temperature control and temperature measurement points |

2-50 points in the tank and mold |

| Test vacuum port |

1-50 vacuum and test is separated |

| Vacuum port |

1-50 vacuum and test is separated.each vacuum port is independent |

| Point temperature error |

1-2 °C |

| Effective length |

1-15m |

| Tank open door |

Manual or hydraulic open door |

| Product |

Carbon Fiber Autoclave, Composite Curing Autoclave, Autoclave Process Composite Material |

Customization:

Custom Composite Autoclave Service

We offer customized industrial autoclave service for composite curing autoclaves and automated pressure autoclaves. Our autoclave is designed to meet the high performance requirements of the most demanding applications. It is equipped with vacuum degree of -0.098Mpa(Absolute pressure) and temperature control and temperature measurement points of 2-50 points in the tank and mold. The cooling rate (empty load) is adjustable from 0-7°C/min, and the working temperature is between 100-450 degree. We offer both manual and hydraulic open door for the tank.

Support and Services:

Composite Autoclave provides technical support and services to customers to ensure their satisfaction. Our technicians are highly skilled and use the latest tools and technology to diagnose and repair any issues that may arise with our products. We offer a range of services including installation, maintenance, and troubleshooting, as well as remote access support. We also provide online training for our customers to help them get the most out of their Composite Autoclave product.

We are committed to providing our customers with the best possible service, and we strive to ensure that their experience with our products is as positive and beneficial as possible. Our team of technicians is available 24/7 to answer any questions or address any issues that may arise. We also provide ongoing support and updates to ensure that our products remain up-to-date and functioning properly.

Packing and Shipping:

The Composite Autoclave is packaged and shipped in a wooden pallet. The pallet is wrapped in a stretch wrap film and then secured to the pallet with strong strapping. The pallet is then loaded into a container for shipping.

The container is then loaded onto the truck for delivery. The truck is secured with tie-down straps to ensure that the container is not damaged during transport. The container is also inspected before loading to ensure that it is in good condition.

The Composite Autoclave is then delivered to the customer. Upon delivery, it is inspected for any damage that may have occurred during transport. If any damage is found, the customer is notified and the product is replaced or repaired, as necessary.

FAQ:

Composite Autoclave

Q1: What is a composite autoclave?

A1: A composite autoclave is a pressure vessel used to process materials at elevated temperatures and pressures. It is primarily used in the aerospace, automotive and energy industries. Q2: What are the benefits of a composite autoclave?

A2: Composite autoclaves offer superior temperature and pressure capabilities, faster production cycles, and improved product quality. Additionally, they are more efficient, require less energy and are more cost-effective compared to traditional autoclaves. Q3: What materials can be processed in a composite autoclave?

A3: Composite autoclaves are capable of processing a wide range of materials, including composites, plastics, elastomers, and ceramics. Q4: What type of controls are available for a composite autoclave?

A4: Composite autoclaves are equipped with state-of-the-art control systems to ensure precise temperature and pressure levels are maintained. The control systems are designed to be user-friendly and offer real-time monitoring, data logging, and advanced safety features. Q5: What safety features are standard on a composite autoclave?

A5: Standard safety features on composite autoclaves include over-pressure and over-temperature cutoffs, emergency pressure release valves, and safety interlocks.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!