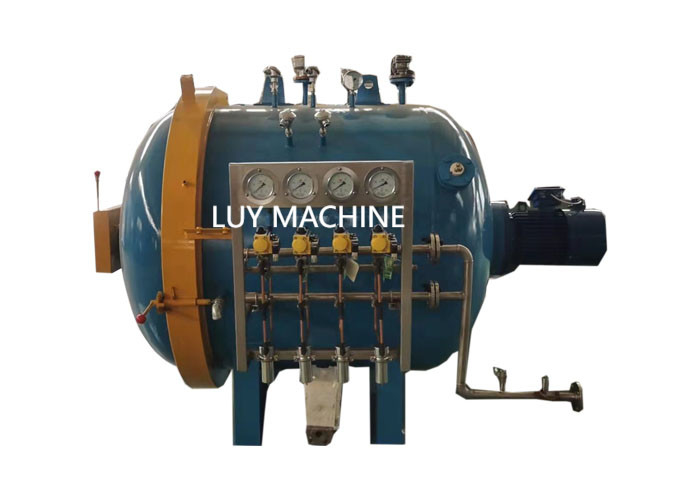

PLC Control 5Mpa Composite Autoclave 7°C/Min 100 - 450 Degree

Product Description:

A Composite Autoclave is an industrial autoclave machine designed for composite curing and composite curing autoclave systems. It is made up of a tank and a mold, with a length ranging from 1-15m. It is equipped with 1-50 vacuum ports and test ports, which are separated and independent from each other. It is also equipped with PLC control and 2-50 temperature control and temperature measurement points. It is an ideal solution for composite curing and composite curing autoclave systems that require precise temperature control.

Features:

- Product Name: Composite Autoclave

- Heating rate (empty load): 0-7°C/min

- Heating ways: Electricity

- Diameter: 600-5000mm

- Working pressure: 0.5-5Mpa

- Working temperature: 100-450 degree

- Industrial Autoclave

- High Temperature Autoclave

- Industrial Autoclave Manufacturer

Applications:

Composite Autoclave is an industrial autoclave system designed for automated pressure autoclaves in various industrial applications. It features a precision pressure error of 0.01Mpa and a fast heating rate of up to 7°C/min. Additionally, it has a point temperature error of 1-2°C, allowing for accurate and controlled temperature settings. It also has a vacuum port ranging from 1-50, allowing for independent vacuum testing. To ensure accurate and efficient operations, it is equipped with a PLC control system.

Composite Autoclave is suitable for a wide range of industrial applications, such as medical device manufacturing, laboratory testing and aerospace engineering. It is also well-suited for composite material processing, where it is capable of curing and sterilizing high-performance composites. With its precision pressure error, fast heating rate and accurate temperature control, Composite Autoclave is an ideal choice for various high-precision industrial autoclave applications.

Technical Parameters:

.

| Parameters |

Specifications |

| Cooling rate (empty load) |

0-7°C/min |

| Point temperature error |

1-2°C |

| Working temperature |

100-450 degree |

| Test vacuum port |

1-50 vacuum and test is separated |

| Vacuum port |

1-50 vacuum and test is separated.each vacuum port is independent |

| Control ways |

PLC control |

| Pressure error |

0.01Mpa |

| Effective length |

1-15m |

| Heating rate (empty load) |

0-7°C/min |

| Tank open door |

Manual or hydraulic open door |

Customization:

Our Composite Autoclave offers a customizable solution for your industrial needs. It features a wide range of features, such as a heating rate (empty load) of 0-7°C/min, PLC control, electricity as the heating way, and temperature control and temperature measurement points of 2-50 points in the tank and mold. The tank material can be Q345R, SS304, 316 or ASME material.

This Composite Autoclave is ideal for high temperature autoclave and carbon fiber autoclave applications. With our customizability and range of features, you can rest assured that our Composite Autoclave will meet your needs.

Support and Services:

Composite Autoclave Technical Support and Service

At Composite Autoclave, we are committed to providing excellent technical support and service for our customers. Our team of highly trained and knowledgeable professionals is available 24/7 to provide assistance with installation, maintenance, and repair of our products.

We provide comprehensive documentation and tutorials, as well as a customer service portal where customers can submit inquiries and track progress. We also offer on-site training and product demonstrations to help customers get the most out of our products.

For any technical questions or concerns, please contact us directly at (insert customer service phone number).

Packing and Shipping:

Composite Autoclave is packaged and shipped using the following methods:

- The autoclave is enclosed in a box with an outer layer of bubble wrap and a layer of foam wrapping the inner box.

- The box is sealed with packing tape and labeled with the shipping address.

- The box is placed inside a larger cardboard shipping box.

- The larger box is sealed with packing tape and labeled with the shipping address.

- The entire package is securely fastened to a pallet and shrink-wrapped.

- The pallet is labeled with the shipping address, and loaded onto a truck for shipping.

FAQ:

Q1: What is the composite autoclave?

A1: The composite autoclave is a pressure vessel used to process composite material under controlled temperature and pressure. It is designed to provide an environment for efficient curing and consolidation of composite material.

Q2: What is the maximum pressure of the composite autoclave?

A2: The maximum pressure of the composite autoclave is up to 2.1MPa.

Q3: How is the composite material loaded into the composite autoclave?

A3: The composite material can be loaded into the autoclave manually or by a conveyor system.

Q4: What is the temperature range of the composite autoclave?

A4: The temperature range of the composite autoclave is between ambient temperature to 200°C.

Q5: What safety features are included in the composite autoclave?

A5: The composite autoclave is equipped with various safety features such as over-pressure protection, over-temperature protection, and emergency stop buttons.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!