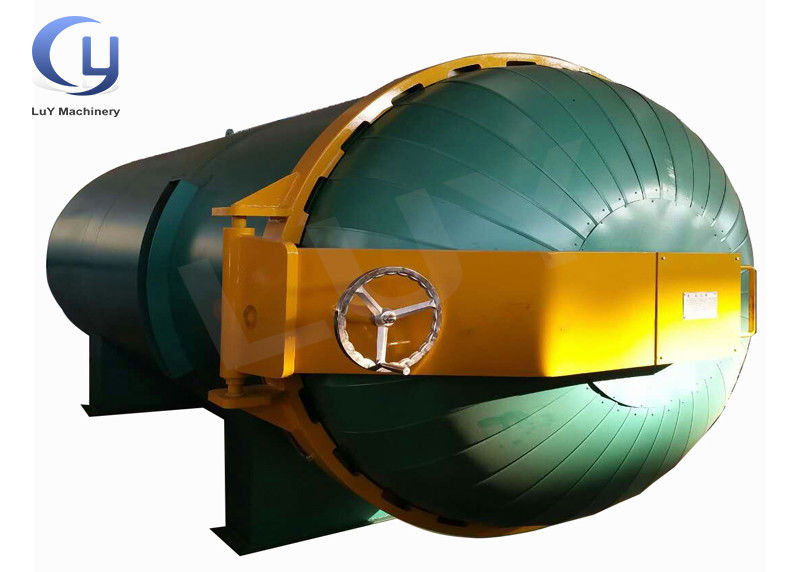

High Configuration Wood Treatment Plant , Wood Pressure Treatment Equipment Customized

Ⅰ Product description

Wood treatment plant is that preventing wood material from Worms, bacteria and other organisms destroy. Such as termite.It is one of wood technology .Adopt differnt chemical preservative to make wood protector,prolong wood using life time and reduce wood consumption.It widely use in protection treatment of pole material ,lumber material ,plate material .

Wood treatment plant mainly used for deep processing of wood, vacuum pressure treatment method, so that the wood to achieve anti-corrosion, pest control, and other purposes. This device can be applied to various water-soluble chemicals such as CCA, ACQ, boric acid, Tanalith E and etc.

Ⅱ Main Model

| Type |

Total Capacity(m3) |

Effective capacity(m3) |

| DN 1200*6000mm |

6.7 |

4.5 |

| DN 1200*8000mm |

9.0 |

6.0 |

| DN 1500*4000mm |

7.0 |

4.71 |

| DN 1500*6000mm |

10.5 |

7.0 |

| DN 1500*8000mm |

14 |

9.4 |

| DN 1800*4000mm |

10.1 |

6.78 |

| DN 1800*6000mm |

15.2 |

10.17 |

| DN 1800*8000mm |

20.3 |

13.5 |

| DN 2000*6000mm |

18.8 |

12.5 |

| DN 2000*8000mm |

25 |

16.7 |

| DN 2000*10000mm |

31.4 |

20 |

| DN 2000*18000mm |

56 |

37 |

Note: The diameter and length can be customized according to users' needs. If the above model is not suitable, please tell us the diameter and length you need. We can customize it for you.

Ⅲ Technical parameters

| No. |

Name |

Unit |

Technical data |

| 1 |

Design pressure |

MPa |

1.58Mpa |

| 2 |

Working pressure |

MPA |

1.0-1.4Mpa |

| 3 |

Vacuum degree(relative) |

MPa |

-0.098MPa |

| 4 |

Power source |

|

380v 3 phase 50hz |

| 5 |

Material |

|

Q345R |

| 6 |

Open door ways |

|

Manual open door ways |

| 7 |

Seam method |

|

Silica gel seam |

| 8 |

Safety ways |

|

Double safety device for door and three safety device for cylinder |

| 9 |

Alarm ways |

|

Automatic light alarm ,over pressure and finish work |

Ⅳ Technology Process

Initial vacuum: we need to keep the tank vacuum before filling of the wood preservative. And it will make the wood preservative into wood cells better. The vacuum degree is -79.8~90kpa and the vacuum time is according to different product(normally 15-60 minutes). when the cylinder in vacuum state, a part of air in the wood was taken out, the resistance will reduce when the wood preservative pushed into wood, so the wood preservative will be easy to get into wood cell.

Filling of preservative into tank: Add the wood preservative by manual valve when the equipment in vacuum state, to make sure the air which in the same condition was stopped in the wood cells. (the degree of vacuum is up to the size of valve)

Boost pressure stage: Begin to boost pressure lowly to 1.0-1.4MPa when the preservative is full of wood tank ,then keep the pressure value until the regulation preservative into the wood.

Pressure relief and discharge preservative: Discharge the pressure after the regulation preservative is absorbed. There will be a little recoil phenomenon(5-15%) during the process.

Final vacuum: Pumping air from the tank to keep the tank vacuum after the preservative discharged from the tank. The purpose is to extract excess wood preservative to reduce the phenomenon of oil dripping.

Recover atmosphere, then open the door and take out of timbers.

Ⅴ Our advantages

1. Double safety protection device :we design double safety device ,manual safety ,and automatic safety interlock ,Only there is pressure inside the tank ,the worker cann’t open the door .

2. Automatic set time function and light alarm ,save worker’s time ,you can set any time in the control box ,once it finish ,it will stop work and alarm

3. Quickly discharge chemical :10 minutes to discharge chemical ,improve treated time

4. Perfect tightness :we use air filled style to seam the door and the system match automatic inlet and outlet air pneumatic valve, it can balance tank pressure well .

5. High efficiency ,save energy ,once the equipment finish vacuum and pressure stage ,the pump will stop ,but whole tank still keep vacuum state

6. Advanced open door method ,only one young girl can open the door easierly

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!