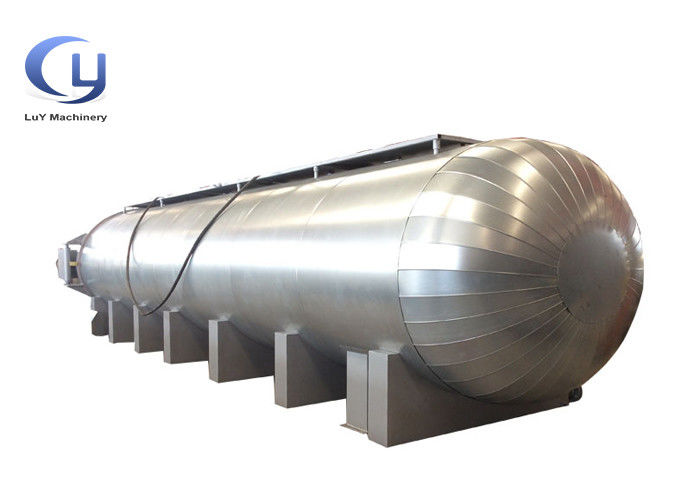

High Configuration Rubber Curing Autoclave With Double Safety Interlocking

Ⅰ Product description

The rubber curing autoclave is mainly used for vulcanization of rubber products, and the vulcanization methods include direct steam heating vulcanization and hot dry air heating vulcanization. Electric power or steam boilers or conduction oil furnaces can be used as heat sources. Automatic control of temperature, pressure and time, safe and reliable performance, easy to use, can be customized for customers according to customer's product technical requirements.

Working principle for electricity steam vulcanizing autoclave

Electric heated tubes are arranged in the bottom of the tank according to certain rules, the heat exchanger linked the electric heated tubes and the water channel. The height of the sink is 5~15mm. The steam which produced by electric heated tubes and water spread from down to up evenly until turn into condensate water pour into the sink after touched the wall of tank and then heat again. The temperature of the tank evenly and the pressure has no error, so it can prevent the different quality of the product because of the uneven temperature and pressure. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

The steam enter into the steam diffusion tube by entrance of steam which at the bottom of the steam vulcanizing boiler and the entrance can be controlled by automatic valve. The steam diffusion tubes vertical arrangement in the bottom of the tank. The small holes which diameters are 3mm,4mm and 5mm on the steam diffusion tube are arranged according to certain rules and angel to ensure that the steam spread in the tank evenly. Thus it can prevent the different quality of the product because of the uneven steam. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Ⅱ Main Model

| Model |

Effective Diameter(mm) |

Effective Length(mm) |

Total capacity(cubic meter) |

| DL800*22000 |

800 |

22000 |

11.0 |

| DL800*64000 |

800 |

64000 |

32.1 |

| DL1000*2000 |

1000 |

2000 |

1.5 |

| DL1200*3000 |

1200 |

3000 |

3.4 |

| DL1500*3500 |

1500 |

3500 |

6.0 |

| DL1800*7000 |

1800 |

7000 |

17.8 |

| DL2500*15000 |

2500 |

15000 |

73.5 |

| DL2600*6000 |

2600 |

6000 |

31.8 |

| DL2800*9000 |

2800 |

9000 |

55.4 |

| DL4500*13000 |

4500 |

13000 |

206.0 |

Note: If the above model is not available, please tell us the diameter and length of the equipment you need. We can customize it for you. The maximum diameter which we can customize is 4.5 meters, the length can be customized according to users' needs.

Ⅲ Technical parameters

| Design temperture(℃) |

150-220℃ |

| Design pressure(Mpa) |

0.6-3.0Mpa |

| Material |

Q345R carbon steel |

| Heating ways |

Direct steam heating or hot air heating |

| Open door ways |

Manual quickly open door or Hydraulic open door way |

| Sealing ways |

Filling air sealing (lifetime1-2year) |

| Control ways |

Semi-automatic control or automatic control |

| Safety ways |

tank door double safety interlock ,tank with three safety interlock |

| Alarm ways |

over pressure automatic alarm ,automatic discharge pressure |

| Temperature uniform |

±1-2℃ |

| Pressure difference |

<±0.01mpa |

Ⅳ FAQ

1. What’s the welding method?

Automatic submerged arc welding, it has advantages of good weld quality and good weld appearance. It also hasn’t arc radiation. And our company has own special flaw detection to ensure the quality of the machine

2. What’s the open door method?

Open door manually, open the door by electricity, open the door by hydraulic. Advanced open door method ,only one young girl can open the door easily.

Automatic pressure safety interlocking method and manual safety interlocking method, it solved the safety problem of wrong operation.

3. Is the control system manual, semi-automatic or full-automatic?

Our basic control system is semi-automatic operation system, and we also can supply full-automatic operation system.

4. What is the heat source?

Steam boiler , conduction oil boiler and electric.

If you do not have the boiler, we can provide you with.

And you can also choose electric heating.

5. What’s the heat preservation way?

Using external thermal insulation.

The galvanized sheets which will not rust in ten years welded and fixed around the equipment and built in insulation cotton to ensure make full use of heat energy. The thickness of the insulation cotton which around the tank is 80mm and the thickness of the insulation cotton which around the head of the equipment is 60mm. It has advantages of easy to transport, long time use without deformation, good insulation effect and low cost.

6. Is it can be customized?

Sure, this rubber vulcanization autoclave can be designed according to customers’ requirements, the maximum to meet different product technology and process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!