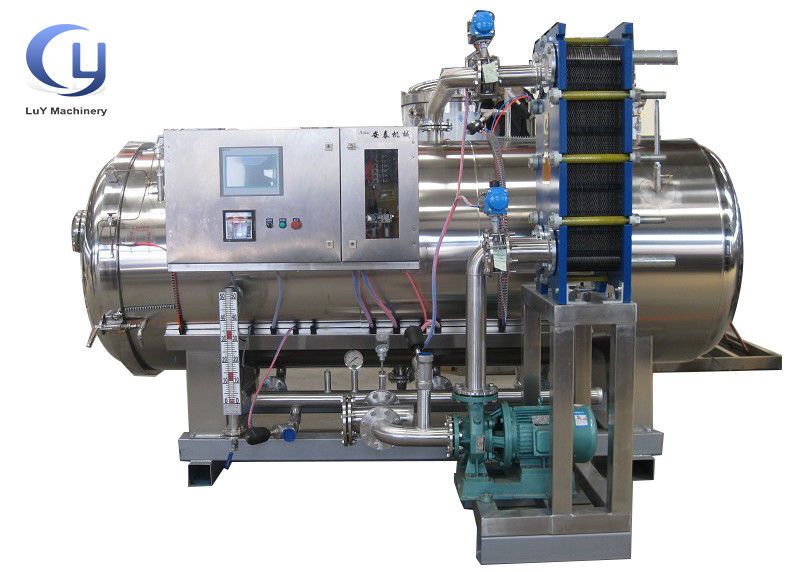

Full automatic Food Sterilizer Machine Passed Government Test Can Be Customized

Ⅰ Product description

This full automatic double layer food industrial sterilizing retort autoclave adopts high temperature and high pressure sterilization technology, double-layer structure, hot water circulation, immersion sterilization and spray sterilization for customers to choose.

The PLC control is used to precisely control the temperature, pressure and sterilization time in the sterilization process. The sterilization formula can be designed according to the type and technical requirements of the customer's products.

The design temperature is 147 degrees, which is mainly suitable for the sterilization of foods such as meat products, dairy products, soy products, canned fruits and beverage products. Suitable for all kinds of high temperature resistant packaging materials: tinplate cans, aluminum cans, vacuum bags, high temperature cooking bags, glass containers and other high temperature resistant plastic containers.

Ⅱ Main Model

| Model |

Total capacity(m³) |

Treat capacity(m³) |

Trolley number |

Basket number |

| ATP700*1200 |

0.46 |

0.25 |

1 |

3 |

| ATP900*1800 |

1.1 |

0.57 |

2 |

8 |

| ATP1000*2400 |

1.8 |

1.0 |

3 |

12 |

| ATP1200*3600 |

4.0 |

2.0 |

4 |

20 |

Note: If the above model is not available, please tell us the treat capacity you need. We can customize it for you.

Ⅲ Technical parameters

| Project |

Technical Data |

| Test pressure |

0.44Mpa |

| Design pressure |

0.35 Mpa |

| Maximum operating pressure |

0.30 Mpa |

| The maximum operating temperature |

143℃ |

| Design temperature |

147℃ |

| Heating method |

Electric heating or using steam boiler as heat source |

| Voltage |

380 V 3 phase 50Hz(can be customized) |

| Material |

SUS304 stainless steel |

| Water quality requirement |

Sterilizing water, cooling water for tap water, not more than 25 mg/L chloride ion content |

Ⅳ Our advantages

In order to heat food uniformly, flow of liquids is changed through circulation pump and exchange valve.

a. Uniform water exchange method, uniform temperature, no dead ends

Circulating water circulated constantly and uniformly in sterilization tank. Ensure uniform heat distribution at any point in the process of heating, insulation and cooling. So the packed foods of different positions of the tray gained the ideal uniform heating effect, effectively eliminate the phenomenon of blind Angle in the process of sterilization. Make the product a longer shelf life. Reduce F value variation and the phenomenon of excessive cooking.

b. High temperature short time sterilization

Using double tank hot water circulation method to sterilization, hot water heated to the temperature of the sterilization requirements before sterilization to shorten the sterilization time and improve work efficiency.

c. High precision sterilization

Using international advanced technology and hot water circulation immersion method to sterilization. Full automatic intelligent control system. Precise temperature control(±0.5°c).

d. Energy saving

Working medium can be recycled, save the energy, time and the consumption of manpower and material resources, reduce the production cost.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!